This clear borosilicate glass perta ins to a group of types of glass, which excel in a high heat and chemical resistance and which have been defined by international ISO 3585 Standard. These types of glass may be utilized in the most demanding sectors, such as chemistry, pharmacy, medicine, biology and food industry.

In a modern automated blending plant pre-treated and blended raw materials are melted in electric resistance furnaces with vertical melt flow and continuous operation. Electric glass melting in Kavalierglass has a 30 years‘ tradition and by the extent of use it is unique worldwide.

Rotary glass blowing automatic machines form thin-walled vessels (such as beakers, flas ks, tumblers and jugs) from a glass drop, impinging from within an automatic feed er. The drop, placed inside the machine on a ring washer, falls through the washer opening and it is stretched partly by its own weight, but, above all, by the effect of air pressure from the glass blowing head, and, it rotates on vertical axis. The glowing flask is gripped all around by two parts of the glass mould, which has the shape of the final product. By an increase of air pressure the product in the mould takes shape, and, upon opening the mould, it slides down on a conveyer. In forming, a technological edge, called coat, is created on glass blowing machines. This coat may be removed inside another machines by melting away. The production line is automatically connected to automatic machines for spout forming and decorative or functional glass printing machines and forming and printing of su ch kinds of products , as may be required.

For the purpose of manufacturing special bottles and jars for medicine or laboratori es, where using Simax glass is advisable or essential, Kavalierglass utilizes a modern automatic machine.

The glowing glass mass in the feeder creates a drop at a temperature of about 1,300 degrees Centigrade, which, falls down, when automatically cut off, into a pressing mould, and, it shall be pressed out in no time using hydraulic pressure. On the one hand, the pressed piece shall be cooled down at press further positions, and on the other hand, it shall be smoothed down and polished by a system of burners. The pressed piece shall be transported by a conveyer belt to the hardening furnace (the tunnel), where, after a new heating, it shall be suddenly chilled by air flow and face hardened. Thus, its heat resistance shall be increased in 50 per cent and the product shall acquire the required properties for all usual heat treatments in the laboratories or at home.

Technically demanding modern automatic production of borosilicate glass tubes as semi-finished products (blanks) for further processing represents a prerequisite for a successful production of a whole range of assortment of laboratory instruments and industrial glass equipment. For the production of glass tubes with a diameter of up to 50mm Kavalierglass utilizes an up-to-date Vello system drawing line, and, glass tubes with larger diameters of up to 170mm are drawn on the equipment of the glass works own design.

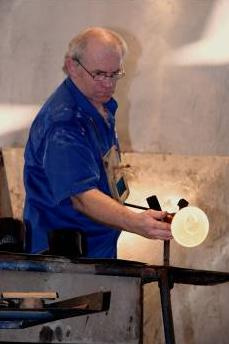

Laboratory and technical glass assortment manufactured in Kavalierglass includes thousands of kinds of products. This is why there are still hundreds of types of products, which are required to be hand-made due to complexity of the form or because of a limited production series. The plant, however, employs glassmakers, who are highly-qualified and skilled in terms of craftsmanship, and, who are able to handle any problem in glass manual forming, be it a modern pan for chicken dietetic grilling, or a 200 litres reactor vessel. Using hand-operated mechanical and hydraulic presses, and, afterblowing the largest products, which are complex in shape, by means of compressed air puts away physical strain and facilitates the glassmakers‘ work. Likewise, finishing operations on manually formed products are made on modern machines, which, as a rule, are of the glass works own design and manufacture.

Glass forming above a blast lamp remains to be the basic technology of each manufacturer of laboratory instruments. On a daily basis, tens of skilled glass blowers in Kavalierglass produce with accuracy and precision even the most complex laboratory equipment and instruments in accordance with drawings and standards. In this activity they make use of mechanically formed glass semi-finished products (blanks) and above the blast lamp they weld not more than just the instrument final assembly. Whole range of operations in glass blowing technology has also been mechanized. Semi-finished products, such as normalized ground glass joints, glass taps and others, are produced, in the first place, mechanically. Graduated cylinders production has been fully mechanized. A part of laboratory vessels is required to be accurately measured and the capacity has to be marked on the product in the prescribed manner. Marking may be performed for the most part using a fast enamelled printing, and, for the production minor part a more conservative process of marking by glass etching is used on customer’s request.

The finishing production of large glass storage tanks, reactor vessels and heat exchangers from the industrial glass equipment programme has proved to be extremely demanding. Flanges with a diameter of up to 600mm are welded on the vessels to ensure the final assembly in a cold state, and, feed and outlet holes adapters, glass taps and bushings for thermometers and stirrers are welded on a defined place of the vessel. Multiple helices of heating and cooling coils are welded on heat exchangers lateral area of a cylinder.

At the end of the manufacturing process of industrial valves, the assembly is performed, during which, using non-glass supplements and connecting parts, metallic flanges, bolts and packings, the whole equipment shall be built up and subject to functional testing. On customer’s request the manufacturer may also perform a final assembly and testing, eventually, commissioning the equipment at buyer’s plant.

Household glass made in series production is sold in sets and assemblies, which are reasonably set up in packing the product. Assembly of non-glass elements and supplements also forms part of the completion. The completion operation is finished by packed products palletization and wrapping the pallet assemblies up in a stretching film. The film covered transport pallet as an up-to-date, highest safety and economic product packing then represents the basic sales and dispatch unit.